Heat Pipe Heat Sinks: Next-Generation Thermal Control Solutions

By 2031, global demand for electronics cooling is expected to reach $11,653.3 million, fueled by growing requirements in data centers, aerospace systems, and renewable energy technologies. As electronic devices continue to operate at higher power densities, conventional air-cooled solutions are struggling to meet thermal performance limits. This growing challenge has made heat pipe heat sinks a preferred choice for advanced thermal management.

These systems combine fin structures with the exceptional thermal conductivity of heat pipes to efficiently spread heat from high-power components. To better understand their value, let’s examine their design, operating principles, and applications that make them essential for maintaining reliability in modern electronics.

Understanding Heat Pipe Heat Sinks

What Is a Heat Pipe Heat Sink?

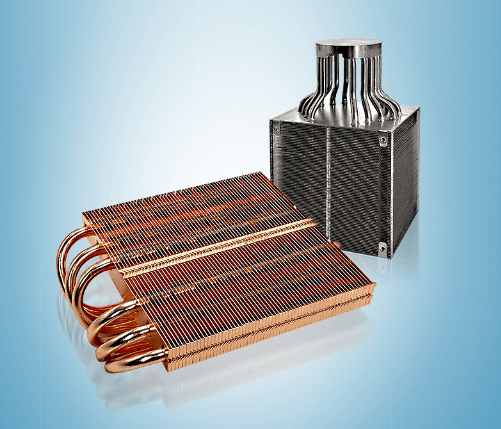

A heat pipe heat sink is a thermal management solution that integrates the passive two-phase heat transfer capabilities of heat pipes with the conductive and convective cooling of traditional heat sinks. This hybrid approach uses the high effective thermal conductivity of heat pipes to transfer heat away from concentrated hotspots and distribute it across a larger surface area for dissipation through convection and radiation.

Inside each heat pipe, a working fluid, such as distilled water, ammonia, methanol, or acetone, circulates between evaporation and condensation zones using capillary action. This process enables extremely low thermal resistance, making the design ideal for high-power-density applications.

Advantages of Heat Pipe Heat Sinks

Heat pipe heat sinks combine efficient heat transport with expanded surface area to deliver superior cooling performance. By spreading heat evenly across the fins, they reduce localized hotspots that can shorten the lifespan of electronic components. Their ability to manage high heat flux levels makes them suitable for cooling processors, GPUs, and power electronics where temperatures may approach 95°C.

Advanced designs are capable of dissipating 300 watts or more, significantly outperforming standard heat sinks that rely solely on air cooling. This enhanced capability makes them essential for high-performance systems.

Development of Heat Pipe Heat Sink Technology

The evolution of heat pipe heat sinks has closely followed increasing thermal demands in computing, aerospace, and telecommunications. As component power densities rose, traditional heat sinks became insufficient for maintaining safe operating temperatures.

This limitation drove the adoption of heat pipe technology in compact devices and systems with restricted airflow. With continued advancements in materials such as copper and sintered metals, modern heat pipe heat sinks have become more adaptable and capable of handling thermal loads exceeding 500 watts in data center and industrial environments.

Design and Performance Characteristics

Core Structural Components

A typical heat pipe heat sink consists of heat pipes, fins, a base plate, and internal wick structures. The heat pipes transfer thermal energy away from the source, while the wick structure enables the return of condensed liquid to the heat source through capillary action. Aluminum fins increase surface area for efficient heat dissipation, and the base plate serves as the primary interface for heat absorption.

Together, these components form a reliable and efficient thermal management system.

How Heat Pipe Heat Sinks Work

Heat pipe heat sinks operate using a two-phase heat transfer cycle. Heat absorbed at the evaporator end causes the internal liquid to vaporize. The resulting vapor moves toward the cooler condenser region due to pressure differences. As the vapor releases heat, it condenses back into liquid form, which is then returned to the heat source by the wick structure.

This continuous cycle enables rapid heat transfer with minimal thermal resistance. Heat pipe heat sinks can achieve thermal resistance values as low as 0.01°C/W, compared to approximately 0.04°C/W for conventional air-cooled heat sinks.

Read also: Corporate Financial Management Techniques 3714655292

Common Configurations and Layouts

Heat pipe heat sink designs vary depending on application requirements. Common layouts include multiple heat pipes embedded in a base plate for CPU and GPU cooling, as well as direct-contact designs that enhance heat transfer efficiency. Some configurations use U-shaped heat pipes to spread heat horizontally, while others stack pipes vertically to maximize cooling in compact spaces.

Fin orientation and density are carefully optimized to balance airflow resistance with thermal performance.

Material Selection

Copper and aluminum are the most commonly used materials in heat pipe heat sink construction. Copper offers a high thermal conductivity of 398 W/m·K, making it ideal for use in heat pipes and base plates. However, its higher density and cost limit its use in weight-sensitive applications.

Aluminum, with a thermal conductivity of 237 W/m·K, is lighter and more cost-effective. It is commonly used for fins where large surface areas are required for efficient heat dissipation.

Advanced Design Innovations

Innovative heat pipe heat sink designs, such as vapor chambers and direct-contact heat pipes, address the thermal challenges of high-performance electronics. Vapor chambers distribute heat evenly across the base plate to minimize hotspots, while direct-contact designs eliminate thermal interfaces between the heat source and heat pipe.

These solutions are widely used in servers and gaming systems where thermal performance directly impacts system reliability and longevity.

Applications of Heat Pipe Heat Sinks

Heat pipe heat sinks are used across a wide range of industries, including:

- Consumer electronics (laptops, smartphones, gaming consoles)

- Data centers and server systems

- Telecommunications equipment

- LED lighting applications

- High-performance CPUs and GPUs

- Industrial automation systems

- Power electronics (MOSFETs and IGBTs)

- Medical imaging equipment (CT and MRI systems)

- Solar power inverters

- Aerospace and satellite systems

- Avionics and military electronics

- Electric vehicle battery management

- Semiconductor manufacturing equipment

In high-performance computing, heat pipe heat sinks can dissipate thermal loads of 100–300 W/cm². In aerospace applications, they provide stable thermal control across extreme temperature ranges from -150°C to +125°C. Industrial power electronics rely on these solutions to maintain operating temperatures below 85°C, ensuring long-term reliability.

Key Benefits of Heat Pipe Heat Sinks

- Enhanced heat transfer through phase-change operation

- Extremely high effective thermal conductivity

- Low thermal resistance over extended distances

- Lightweight and compact design

- Flexible installation orientation

- Rapid response to thermal load changes

- Capability to manage high heat flux densities

- Passive operation with no moving parts

- Long service life and high reliability

- Customizable size and geometry

- Suitable for vacuum and space environments

- Minimal maintenance due to sealed construction

These advantages make heat pipe heat sinks an ideal solution for space-constrained and high-performance systems, allowing designers to achieve aggressive thermal targets without active cooling methods.